SKOURIES (GREECE)

The Skouries project is a copper-gold deposit located on the Halkidiki Peninsula in northern Greece.

This copper-gold porphyry deposit will be mined using a combination of conventional open pit and underground mining techniques. Based on the 2022 Project Feasibility Study, the initial life of mine is 20 years, and it is expected to produce on average 140,000 ounces of gold and 67 million pounds of copper per year. First copper-gold concentrate production is expected toward the end of the first quarter of 2026, with commercial production expected in mid-2026.

Skouries Project Progress

Updated: December 2025

Advancing Skouries

As of December 31, 2025, Phase 2 construction was 78% complete. First production of copper-gold concentrate is expected toward the end of the first quarter of 2026, with commercial production expected in mid-2026.

Commercial terms for concentrate off-take have been agreed to with contract execution expected in the coming weeks. Concentrate off-take agreements will cover approximately 80% of the copper concentrate for a 2 to 3 year term depending on the agreement and with the market for clean copper concentrate tight we expect to achieve significantly better economic terms than those assumed in the 2022 feasibility study assumptions.

In Q1 2025, the capital cost estimate was revised to $1.06 billion and the project remains fully funded. The Commercial Loan Facility and the RRF Facility totalling €680.4 million ($798.9 million) are fully drawn.

- As we report Skouries capital costs in US dollars, the persistent strength of the Euro through the end of 2025 has led to an unfavorable foreign exchange impact, estimated to be approximately $43 million (through to commercial production). The impact to our cash balances has been materially mitigated through foreign exchange gains of approximately $20 million on Euro cash holdings through the end of 2025.

Project capital totalled approximately $137 million2 in Q4 2025 and approximately $475 million2 for 2025, slightly higher than the revised guidance range of $440 to $470 million as we continued to accelerate work across several non-critical path areas while proactively advancing site-wide de-risking initiatives. At December 31, 2025, cumulative project capital invested towards phase 2 of construction totalled $980 million2.

In Q1 2025, an additional $154 million was allocated for accelerated operational capital to complete additional pre-commercial underground and open-pit mining and accelerate the purchase of higher capacity mobile mining equipment (originally expected to be purchased post commercial production as part of the contract mining fleet).

Accelerated operational capital costs are expected to increase through to commercial production by approximately $24 million to support:

- Further accelerated underground development: Development rates are exceeding plan with multiple headings opened. We expect to continue accelerating development rates through 2026 to de-risk underground production and facilitate a faster ramp up of the underground in 2027. This will also allow us to increase the number of test stopes planned for 2026 from two to four, resulting in an addition of approximately 145,800 tons in 2026.

- Increase stope widths from 15 metres to 20 metres, resulting in an addition of approximately 24,300 tons per stope thereby increasing productivity and lowering costs.

Accelerated operational capital was approximately $35 million2 in Q4 2025 and approximately $86 million2 for 2025, in line with the guidance range of $80 to $100 million. As of December 30, 2025, cumulative accelerated operational capital totalled approximately $93 million2.

2 These figures are preliminary in nature.

As at December 31, 2025, overall project progress was 90% when including the first phase of construction and 78% complete for phase 2 of construction.

Primary Crusher

Progress continues on the construction of the crusher building structure with the concrete now complete. The primary crusher is mechanically complete and set in position, with work continuing on finalizing the electrical installations. Conveyors from the primary crusher through the coarse ore stockpile to the process plant have been installed and belt installations commenced in January 2026.

The stockpile dome foundation is complete, and assembly of the dome structure is progressing. Two of the three reclaim feeders and associated chute work have been installed, with pre-assembly underway on the remaining reclaim feeder. Installation of the prefabricated electrical distribution room is scheduled for late January 2026.

Process Plant

Work in the process plant remains focused on mechanical installations, piping, cable tray and cabling in preparation for first ore. High and medium voltage electrical distribution from multiple substations within the process plant network are advancing, and the control building structure is complete with electrical work underway across all areas.

The lime plant, flotation blowers and compressors buildings are mechanically complete. The prefabricated electrical distribution room for the compressors has been installed, with cable and terminations progressing. Reagent areas are advancing well through various stages of mechanical, piping and electrical installations.

Thickeners

Two of the three tailings thickeners required for initial start-up are mechanically complete, with electrical cabling and instrumentation installation underway. The third tailings thickener is not required for start-up and is progressing in line with its planned start-up following first concentrate production.

Water testing has been completed, and piping installations have advanced as the pipe rack installations are completed. Work is advancing on the associated infrastructure, including the pumphouse building piping and electrical work and tank installations in the flocculant building. Electrical installations in the thickeners’ secondary substation building are in progress, with cable and terminations planned for late January 2026.

Filtered Tailings Plant

Work continues to progress on the filtered tailings plant, which remains on the critical path. The filtered tailings building structural steel installation is substantially complete, with cladding of the building planned to commence by the end of January 2026.

Mechanical work advanced with all six filter presses and associated swivel doors, feeders and conveyors completed. Pipe and cable tray installation progressed as planned. The compressor building steel structure is complete, and all six compressors and air receivers are mechanically complete.

The filter plant tank farm construction has progressed with three tanks complete and the remaining two tanks assembled and water-tested, with internal coating work now underway. The clarifier water tank construction has progressed to plan.

The prefabricated electrical distribution room has been installed, with cable tray and electrical installation advancing.

Work continues on tailings handling infrastructure including a horizontal and downslope stacking conveyor system. This area brings some added complexity, but the team is actively managing it.

Powerline

The powerline, main and secondary substations are advancing to support start-up in Q1 2026. Designs have been approved by the relevant authorities and procurement activities are substantially complete. While these milestones reflect strong advancement, the schedule has been modestly compressed due to resource availability.

Pre-commissioning of the concentrate filter presses has been completed, along with all water testing in the flotation cells and tanks. Pre-commissioning of the pebble crusher is complete, including first fills and completion of construction punch lists. The pebble crusher area has been energized, and hot commissioning of the conveying and process control systems has been completed. Pre-commissioning of the fire, utility, and process water systems has started. Piping and cable installations continued to ramp up during the quarter, with a focus on flotation, grinding, tails filtration, and primary crushing. Commissioning of these areas is expected to commence as sub systems are completed by the construction team.

Integrated Extractive Waste Management Facility

Construction of the Karatzas Lakkos (KL) embankment progressed steadily, with continued advancement of underdrain installation, commencement of the engineered fill raise of the dam, and preparatory works for the next phase of cut-off trench construction.

Work is underway to prepare a dedicated area for the initial placement of tailings, which is expected to simplify the ramp-up process.

Construction of the low-grade ore (LGO) stockpile embankment continued, with the lower section advancing beyond the milestone elevation of 340 RL.

Enhancements were made to the construction of the Water Management System, notably the completion of the coffer dam and the implementation of a piling program to ensure the structural integrity of the KT2 diversion channel. The Water Management System performed well during recent rainfall events, protecting construction activities within the KL and LGO areas and ensuring that both contact and non-contact water diversion systems operated as planned.

The intermediate water treatment plant (IWTP) mechanical installations are well underway, while water treatment plant (WTP) foundation works commenced as planned.

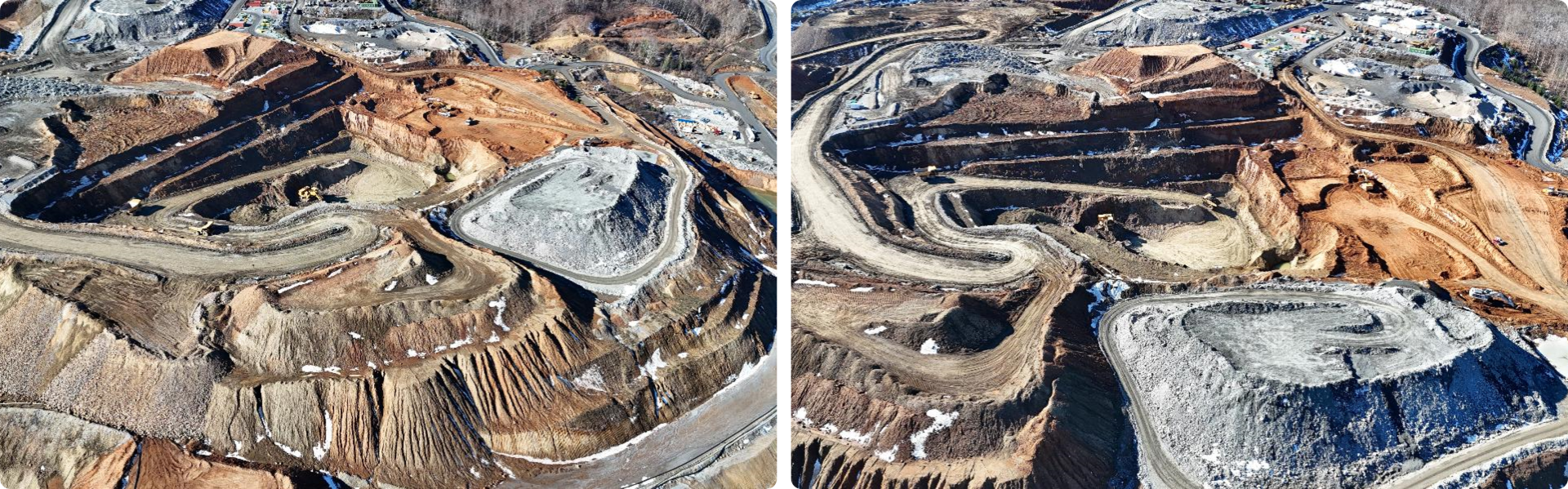

Open Pit Mining

The open pit mine successfully continued to ramp up during Q4 2025 with four crews operating ahead of plan in building ore stockpiles for the process plant start-up. At the end of Q4 2025, there was approximately 1.2 million tonnes of open pit and underground ore on stockpiles3, containing approximately 47.3 thousand ounces of gold and 12.5 million pounds of copper. Grade control drilling covering 95% of the Phase 1 open pit has been completed and confirmed the first three years of production.

Underground Development

Underground access development rates continued to accelerate. A total of 1,155 metres of underground development was completed in Q4 2025. During 2025, underground development totalled 3,092 metres, which was approximately 900 metres more development than budgeted during the year.

The test stope program delivered high quality results during the quarter. The first of two test stopes was completely mined out and the second test stope mining will be completed in February. Each test stope mined to date is expected to provide approximately 72kt of ore, with dimensions of 60 metres in height and an area of 30 by 15 metres. Ore fragmentation has exceeded expectations, and stope cavity monitoring and extraction has met our expectations. This success has increased our confidence in the planned trial of four larger test stopes in 2026, each designed at approximately 97kt per stope with dimensions of 60 metres in height and an area of 30 by 20 metres per stope.

Semi-autonomous ore loading and open stope drilling, with operators on surface (no operator on the equipment), was successfully used during the mining of these two test stopes. This technology enables a single operator to control several pieces of equipment simultaneously, increasing safety, drill accuracy and productivity, reducing idle time between shifts and during blast clearance, and decreasing associated costs.

Processing

Additional testing of tailings filter cloths is underway for the infill drilling program and from bulk samples from the open pit ore already mined and stockpiled. An initial inventory strategy has been established to ensure operational resilience and continuity of supply of filter cloths. This strategy includes maintaining six complete cloth sets sourced from three different vendors.

Engineering and technical optimization efforts continued for the start-up tailings placement area, and operational readiness activities for tailings stacking.

Workforce

As at December 31, 2025, there were approximately 2,350 personnel working on site, including 415 Skouries employees of which 397 were Skouries operational personnel.

KEY HIGHLIGHTS

Location

Mine type

Metals mined

Initial expected mine life

Deposit type

Ownership

*Based on Proven & Probable Mineral Reserves. Refer to Reserves and Resources for more information on Mineral Reserves.

Virtual Tour

Best-in-class Environmental Design

Filtered Tailings

The Skouries project design includes filtered tailings, an innovative method that makes the tailings management process safer and provides additional environmental benefits compared to other tailings management options. During mining, ore is crushed, ground and processed to separate valuable minerals from the surrounding rock. The residual leftover rock and water from this process is called tailings. Traditionally, tailings were stored in liquid form in large facilities, known as tailings ponds. Modern filtered methods remove the excess water resulting in a sandy material which is then stacked and compressed. Less space is required for its storage into tailings management facility areas (TMF).

At Skouries, only one TMF will be required, instead of the two that were planned in the initial design and would have been required in the case of traditional liquid tailings management.

Eldorado has used this technology successfully at our Efemçukuru operation in Türkiye and at our Olympias Mine in Greece. Filtered tailings offer major environmental benefits such as:

Geotechnical stability

Up to 90% of the water is removed from the tailings using filtration. These de-watered solids (similar to a moist sand) are then conveyed and compacted within the storage facility to form a geotechnically stable & solid mass.

Water savings

Filtered tailings technology enables us to maximize water recycling and re-use it in the production cycle, thereby minimizing the consumption of fresh water.

Smaller footprint

Filtered tailings result in up to a 40% smaller environmental footprint, further minimizing environmental impact.

Protection of Water and Facilities

We are reducing water consumption with targeted projects, such as filtering and recycling. We are also reducing groundwater inflows by pre-draining waters and re-injecting them into the aquifer. For water outside the mine site, we have constructed water diversion channels to keep surface waters from even entering the mine site. For water that unavoidably comes into contact with mining activities at the mine, we will both have a water treatment plant and re-use water in day-to-day operations.

Parallel Rehabilitation

The rehabilitation of liquid tailings disposal sites is usually possible after the end of a mine’s lifetime. Thanks to the filtered method, due to the solid form of the tailings, it is possible to gradually regenerate the disposal facilities in parallel with mining activities. That means that the site will be rehabilitated and ready to hand back to the local community sooner after the end of mining activity.

Backfilling tunnels & open pit with mining tailings

Part of the pre-strip material from the open pit is used to build the waste rock dam, water management-ponds and various other site infrastructure works. The excess will be used to gradually rehabilitate the tailings management facility. Mining tailings will be used to fill in the areas that were mined out in the underground mine, as well as the open pit to restore the original terrain.

90%

Water removed from tailings

40%

Smaller environmental footprint with dry-stack technology

Indicative Operating Data

The initial mine life is 20 years, based on Skouries Technical Report (NI 43-101) published January, 2022

| Total Mineralized Material Mined | 147 Mt |

| Average annual gold production | 140,000 oz |

| Average annual copper production | 67 Mlbs |

| Average cash operating costs (LOM) | $(365)/oz |

| Average AISC (LOM) | $(6)/oz sold |

| Gold recovery | 83% |

| Copper recovery | 90% |

| Au grade | 0.77 g/t Au |

| Cu grade | 0.50% Cu |

| Initial Capital Costs (US $) - Initial Phase 1 Capex | $845 M |

| Total sustaining capex (US $) | $850 M |

| Gold price | $1,500/oz |

| Copper price assumption used in financial analysis | $3.85/lb |

| (US $) | $1.3 B |

| IRR (after tax) | 19% |

| Payback period | < 4 years |

Geology and Mineralization

The Skouries porphyry copper-gold deposit is centred on a small (less than 400m in diameter), pencil-porphyry stock that intruded schist and gneiss of the Paleozoic Vertiskos Formation of the Serbo-Macedonian Massif, NE Greece. Mineralization extends for more than 920m depth from surface.

The porphyry is characterized by at least four intrusive phases that are of probable monzonite to syenite composition, but contain an intense potassic alteration and related stockwork veining that overprints the original protolith.

Potassic alteration and copper mineralization also extend into the country rock; approximately two thirds of the measured and indicated tonnes and 40% of the contained metal are hosted outside the porphyry.

The potassic alteration is syn- to late-magmatic in timing and is characterized by K-feldspar overgrowths on plagioclase, secondary biotite replacement of igneous hornblende and biotite, and a fine-grained groundmass of K-feldspar-quartz with disseminated magnetite.

Four main stages of veining are recognized: 1) an early stage of intense quartz-magnetite stockwork; 2) quartz-magnetite veinlets with chalcopyrite ± bornite; 3) quartz-biotite-chalcopyrite ± bornite-apatite-magnetite veinlets; and 4) a localized, late stage set of pyrite ± chalcopyrite-calcite-quartz veins. The host porphyry and potassic alteration at Skouries were coeval and formed during the Early Miocene.

EXPLORATION

Exploration at Skouries is focused on identifying and testing porphyry targets within the project area, including the Tsikara and Fisoka prospects. Ongoing targeting activities include geological mapping, systematic soil sampling and geophysical surveying.

Skouries Project Brochure

REPORTS

| REPORT TITLE | LINK |

|---|---|

| Skouries Technical Report - January 2022 | Download PDF |

| Skouries Technical Report - March 2018 | Download PDF |

| Skouries Technical Report - July 2011 | Download PDF |

Environmental and Social Impact Assessment (ESIA)

| REPORT TITLE | LINK |

|---|---|

| Non-technical summary (NTS) | Download PDF |

| Complete assessment file (ZIP) | View Reports |

| ESIA appendices | View Reports |

| ESMS framework | Download PDF |

| Stakeholder Engagement Plan | Download PDF |

| E&A Management Plans | View Reports |

| Environmental & Social Action Plan | Download PDF |

Regulatory Environmental Impact Assessment (EIA)

| REPORT TITLE | LINK |

|---|---|

| Non-technical summary (NTS) | Download PDF |

| Complete assessment file | View Reports |

| EIA appendices | Download PDF |

| EIA maps / drawings | View Reports |